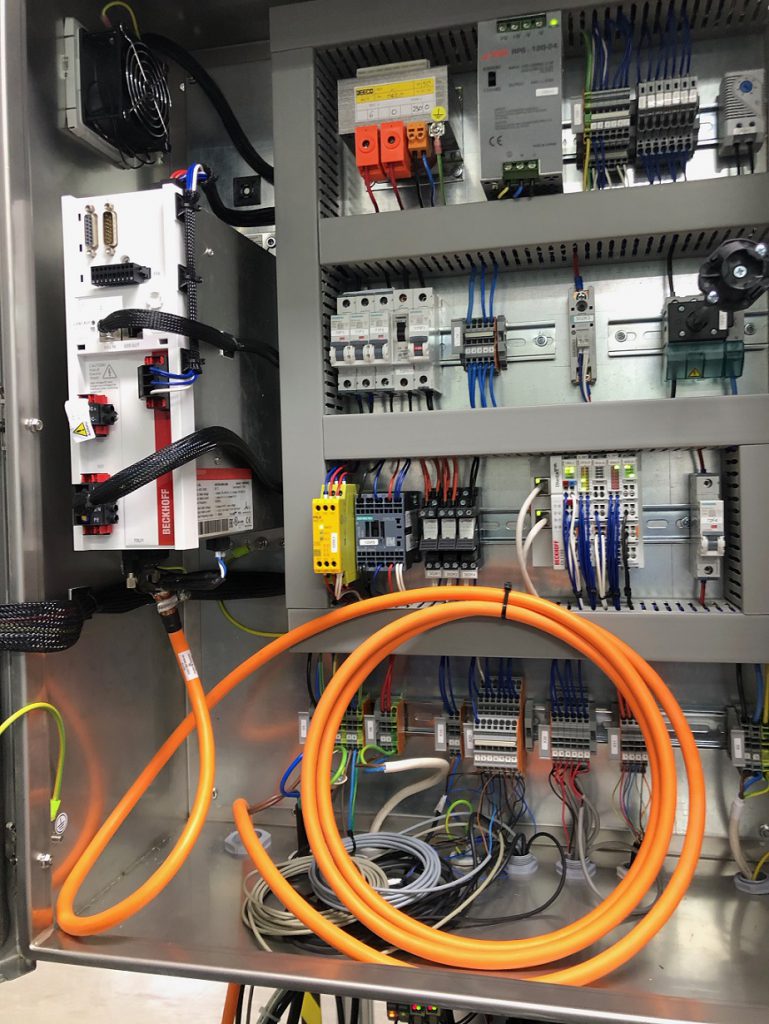

[ezcol_1half]The Control cabinet for a filter making machine, was one of the projects that we at JMartans undertook in 2020. After a free consultation meeting with the customer, we proposed our solution for the redesign and reengineering of their existing machine.

To realize this project we used top quality equipment from Beckhoff Automation , Siemens and, for the safety, PNOZ X2 from PILZ.

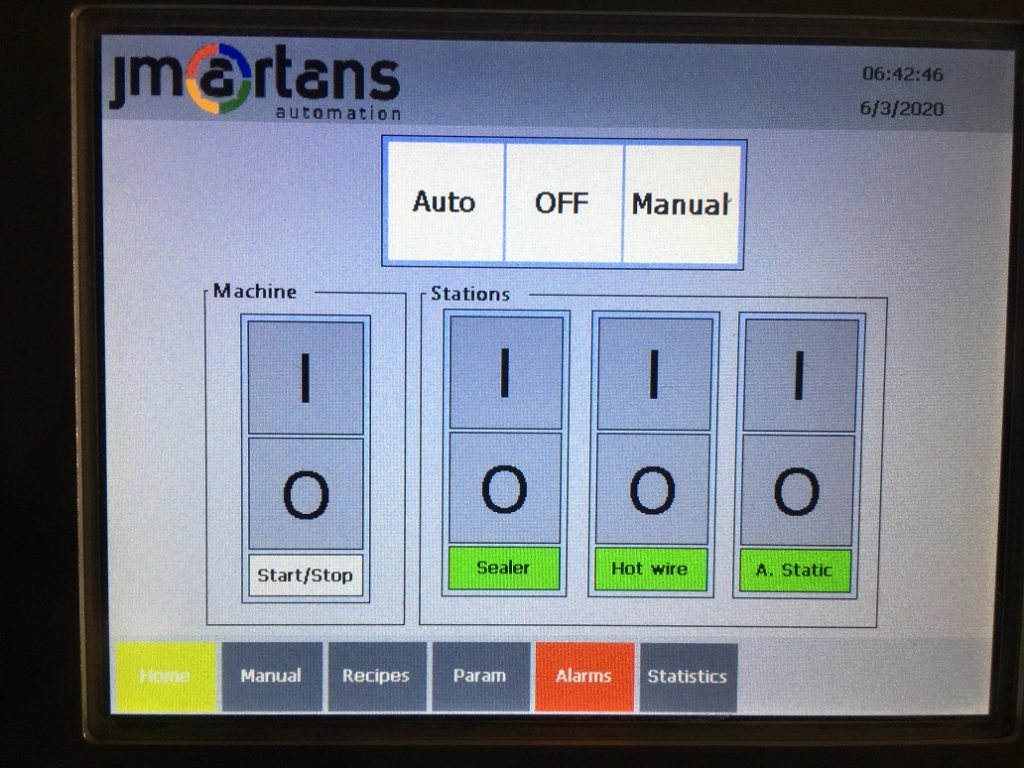

From the HMI the technician can diagnose the current status of all field devices and operate each of them manually, if the required conditions for the devices are satisfied. Furthermore, the supervisor can monitor how many parts are produced daily and how many parts are produced per hour.[/ezcol_1half] [ezcol_1half_end]The machine sequence is as follow:

- On power up the customer chooses a recipe and enables the required stations for the selected recipe.

- Index tape with length A (A being recipe length + excess length)

- Hold tape for time Z

- Cut for time X

- Heater down/up and stay in position (alternating every cycle)

- Welding-on for time Y

- Restart cycle indexing with length B (B being recipe length).

The machine will stop and notify the operator when the batch count is reached. [/ezcol_1half_end]

Beckhoff Built-in panel PCs are ideally suited as small controllers for machine construction and plant engineering applications in conjunction with TwinCAT automation software under Windows Embedded Compact 7. CP66xx-xxxx, incorporating TwinCAT 3 and with integrated visualization was therefore perfect for this application.

The AX5000 Digital Compact Servo Drives (1-channel) are very flexible with regard to the motors that can be connected: different motor sizes and types such as synchronous, linear, torque and asynchronous motors can be connected without additional measures. The multi-feedback interface supports all common standards. For this project, the amplifier had also an integrated safety card (AX5801) with stop functions (STO, SS1).

The AX5000 Digital Compact Servo Drives (1-channel) are very flexible with regard to the motors that can be connected: different motor sizes and types such as synchronous, linear, torque and asynchronous motors can be connected without additional measures. The multi-feedback interface supports all common standards. For this project, the amplifier had also an integrated safety card (AX5801) with stop functions (STO, SS1).

The Servo motor used for the feeding of the filter machine is a Bekchoff AM8032-xxxx with planetary gearbox.

The Servo motor used for the feeding of the filter machine is a Bekchoff AM8032-xxxx with planetary gearbox.

Motor cable was a Beckhoff ZK4500-8022-xxxx which is a highly flexible, drag-chain suitable cable with 5 million bending cycles, including power and signals.

[ezcol_1fifth]A Siemens 1-phase semiconductor relay was used to control the heating element voltage. The use of a solid-state relay means that the switching action time is much faster than a normal switching contactor.[/ezcol_1fifth] [ezcol_1fifth]EL1809 digital input terminal acquires the binary control signals from the process level and transmits them, in an electrically isolated form, to the higher-level automation device.[/ezcol_1fifth] [ezcol_1fifth]EL2809 digital output terminal connects the binary control signals from the automation device on to the actuators at the process level with electrical isolation.[/ezcol_1fifth] [ezcol_1fifth]EK1101 coupler to connect EtherCAT with the EtherCAT Terminals (ELxxxx). A station consists of coupler, any number of EtherCAT Terminals, an bus end cap or an EK1110 EtherCAT extension.[/ezcol_1fifth] [ezcol_1fifth_end]EL3681 digital multimeter terminal enables measurement of currents and voltages in a wide input range. The measuring ranges are switched automatically.[/ezcol_1fifth_end]