Custom Pump Control Panel for High-End Printing Press BMS

Scope:

Design and build pump cabinet control panel as part of the BMS.

Customer type of business:

Highend Printing Press

Service:

Design, Cabinet Building, Programming, Documentation, Installation, Commissioning.

The challenge:

Design, fabricate, and commission a custom control panel to manage multiple pumps as part of the facility’s chilled water distribution system, integrated within the Building Management System (BMS).

Additional info:

Read below for Implementation Process and Results

Control Panel Implementation Process:

JMartans Automation engineered a custom-built control cabinet to meet the client’s exact requirements. Key elements of the solution included:

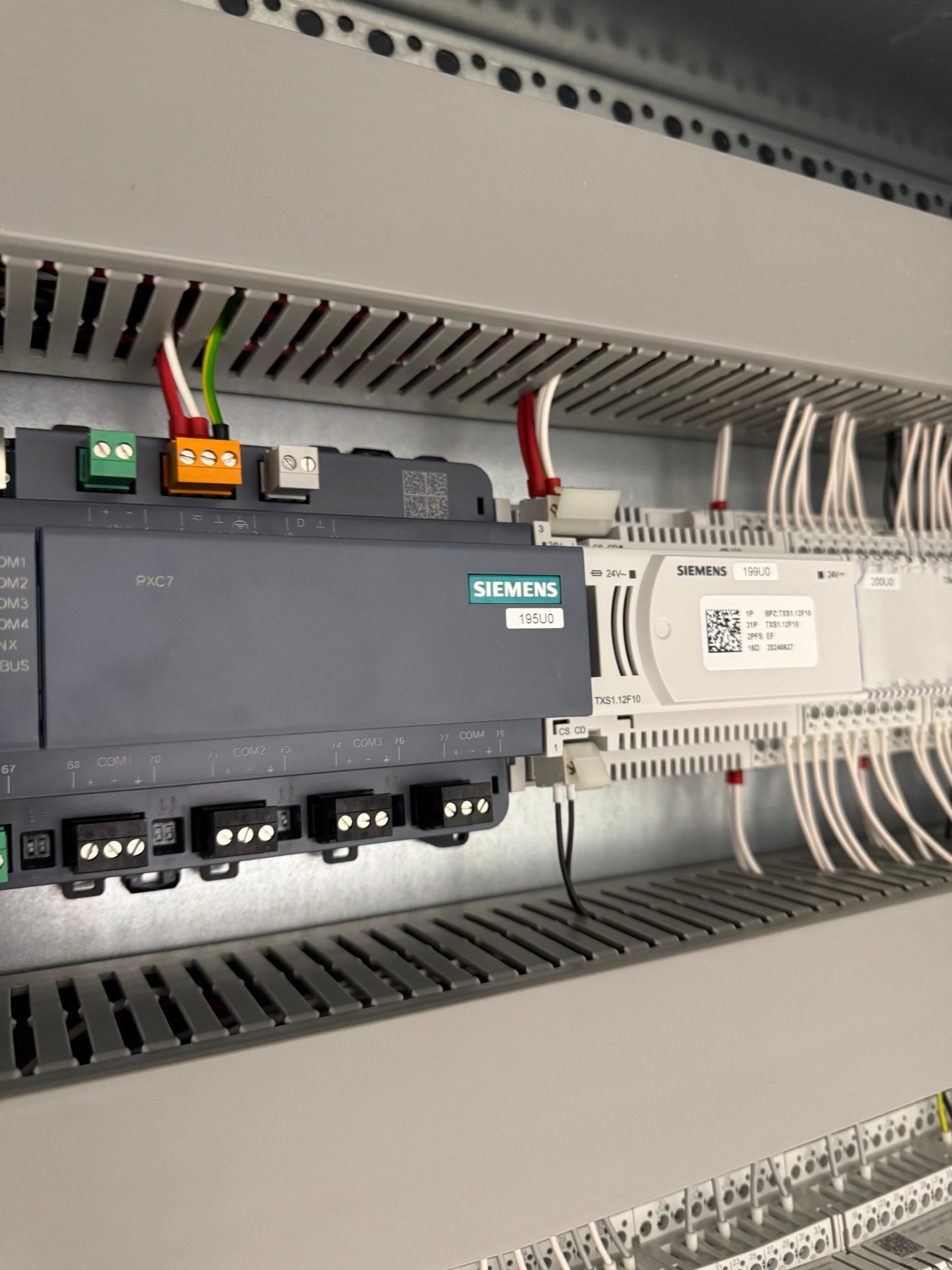

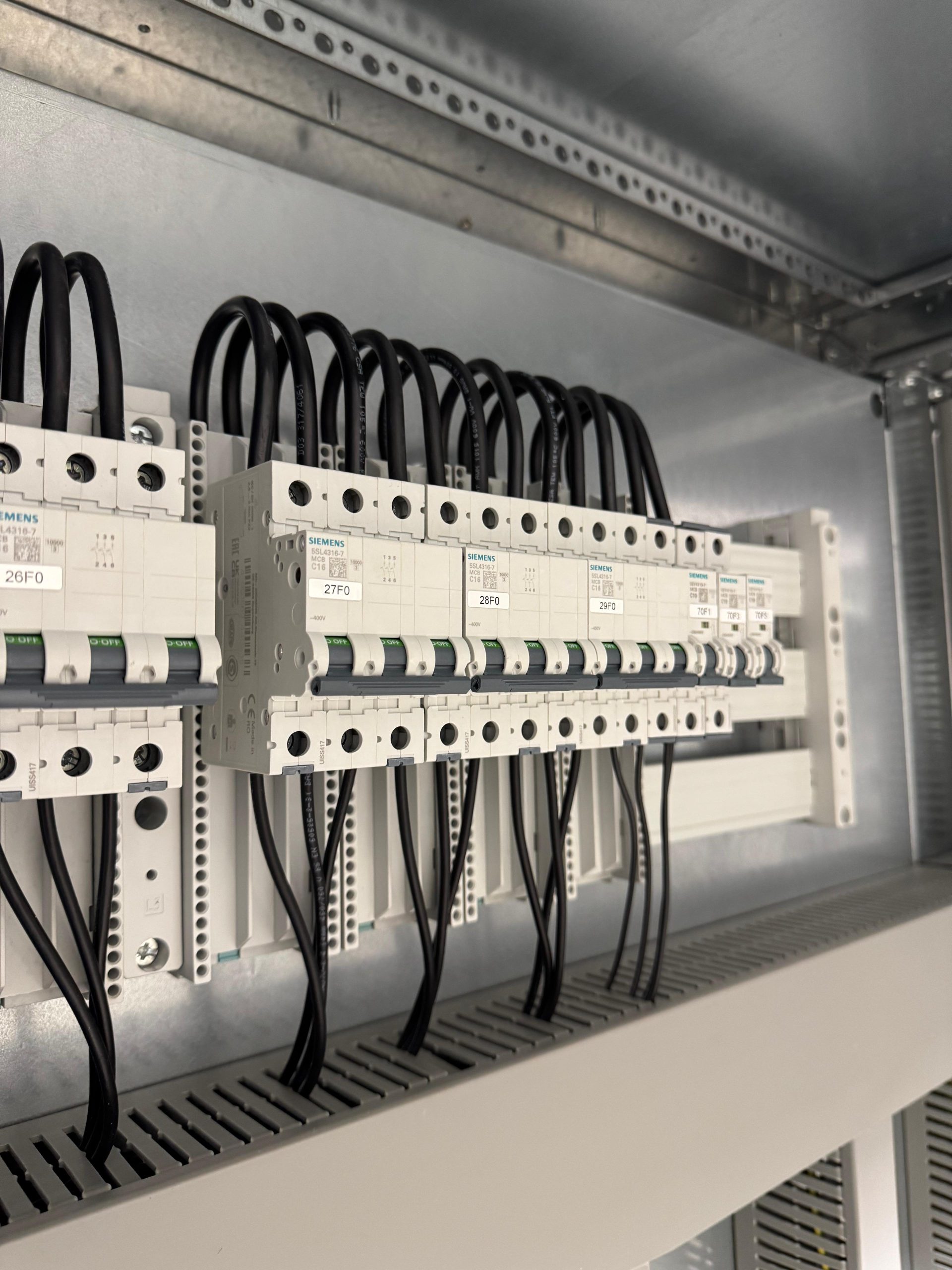

- Cabinet Construction:

The control panel was housed in a Siemens industrial enclosure and built at JMartans’ premises to ensure quality control and precision. - Variable Speed Control:

Multiple ABB variable frequency drives (VFDs) were installed to independently control each pump, allowing for energy savings and precise flow control. - System Control:

A Siemens PLC was programmed to execute all control logic, including pump sequencing, fault handling, and BMS communication. - User Interface:

A Siemens HMI was integrated into the cabinet, enabling local operation, system visualization, and diagnostics. The HMI also allowed for secure remote access for external control and monitoring. - Documentation:

Full electrical drawings and user documentation were provided to support future maintenance and modifications.

Results and Benefits:

As part of the complete BMS, the pump control system delivered immediate operational benefits. The client gained full control of each pump in their chilled water distribution, leading to significant energy efficiency gains and a reduction in manual intervention. The high quality of components used, combined with meticulous workmanship, ensures long-term system reliability and performance.