Our customer for this project is a leading printing company in the region that specializes in the production of plastic products. They had been using an old printing machine that required constant maintenance and repairs. Recently, they approached our company with a request to upgrade their existing printing machine into a manual loading machine and to introduce a 7th print unit into it. In this case study, we will discuss how we successfully executed this project and delivered a machine that met their specific needs.

Project Scope:

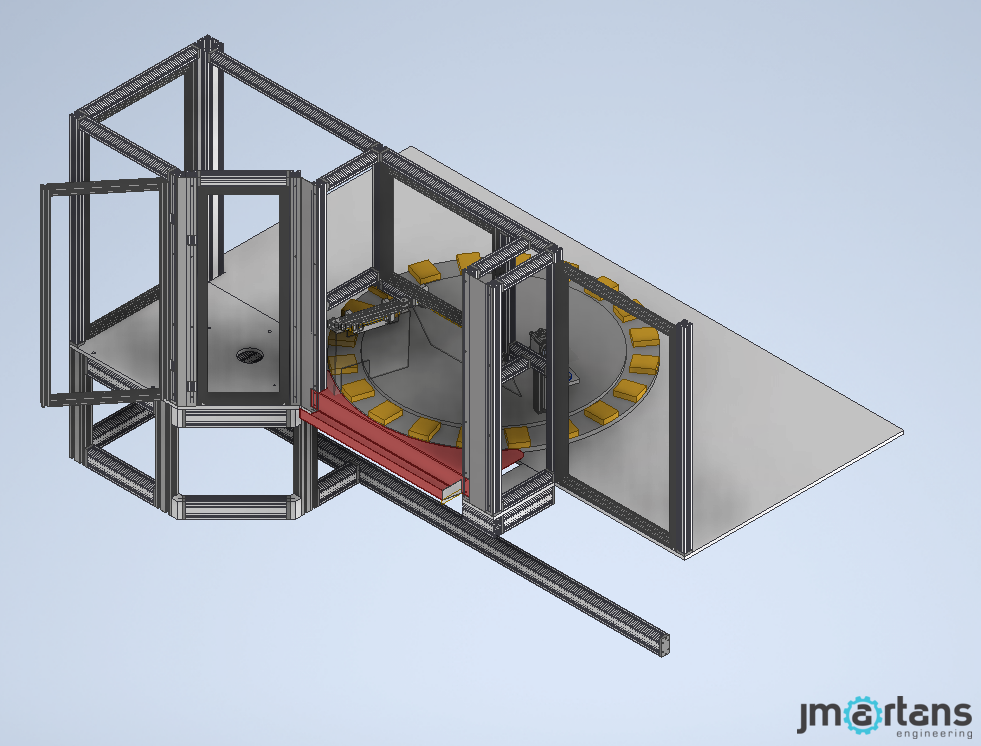

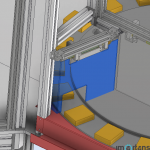

The project scope was to convert the existing printing machine into a manual loading machine, which would allow the operator to manually load the material to be printed. Additionally, a 7th print unit was to be added to the machine to increase the printing capacity. We suggested to introduce a transparent guard be installed to provide visibility of the printing process, and safety switches be added to ensure the operator’s safety during operation.

Project Execution:

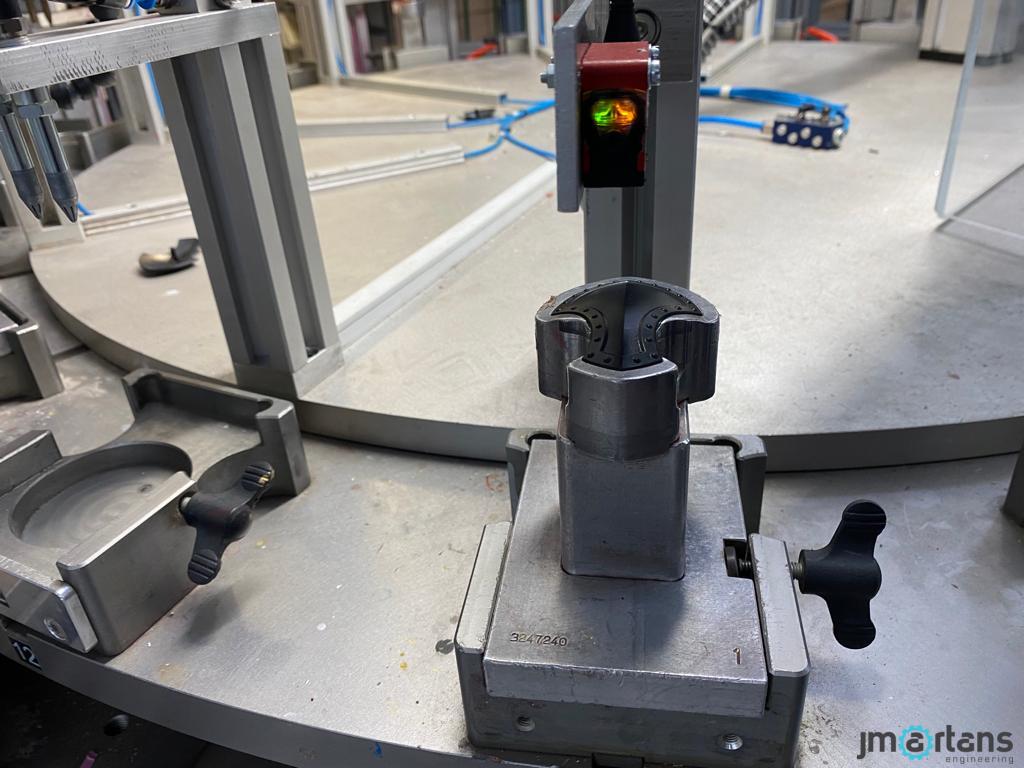

Our team of experienced engineers and technicians carefully evaluated the customer’s requirements and came up with a detailed plan for the machine upgrade. First, we disassembled the existing printing machine and removed the automatic loading mechanism. We then installed a manual loading mechanism, which allowed the operator to load the material to be printed manually.

Next, we added a 7th print unit to the machine to increase the printing capacity. We carefully designed and integrated the new print unit into the machine, ensuring that it worked seamlessly with the existing print units.

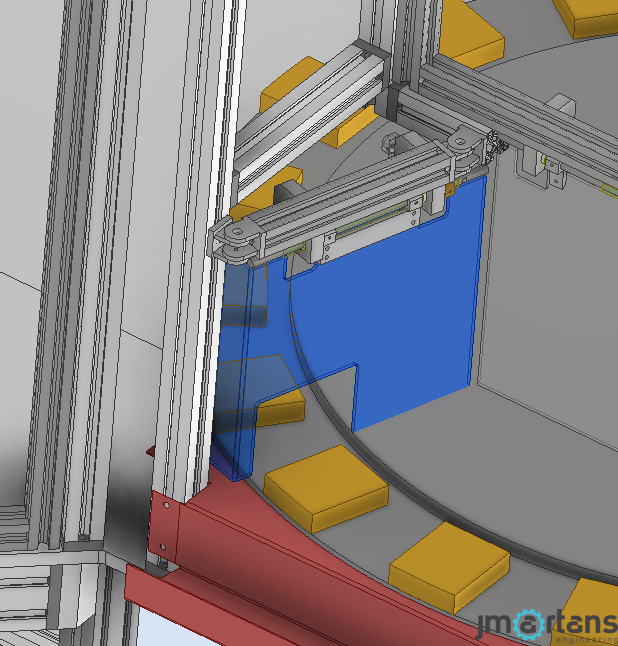

To ensure the operator’s safety, we installed a transparent guard around the printing area, which provided visibility of the printing process. We also added safety switches to the machine, which were connected to specially-designed CAM units, manufactured in-house. These switches automatically shut off the machine if the operator accidentally opens the guard during operation, preventing any injuries or accidents.

Finally, we provided all the necessary mechanical and electrical documents according to the harmonized essential health and safety requirements for machinery. This ensured that the machine was fully compliant with all the relevant safety regulations and standards.

Conclusion:

In conclusion, we successfully executed the machine upgrade project for our customer, delivering a machine that met all their specific needs. We converted the existing printing machine into a manual loading machine, added a 7th print unit, and installed a transparent guard for visibility of the printing process. We also added safety switches to ensure the operator’s safety during operation. The machine was fully compliant with all the relevant safety regulations and standards, and the customer was satisfied with the results.