[ezcol_1half]Based in Mosta technopark in a 600 sqm factory, JMartans Automation can delivery full electrical and mechanical solutions for all kind of industries, from automotive to food & beverage, packaging, pharmaceutical and so forth. With over 15 years of experience locally and abroad we can assist our customers in optimizing their production line. We offer:

- 24/7 repair service

- Design and build of control cabinets

- Supply of electrical and electro-mechanical spare parts

- Industrial automation

- Building Automation[/ezcol_1half]

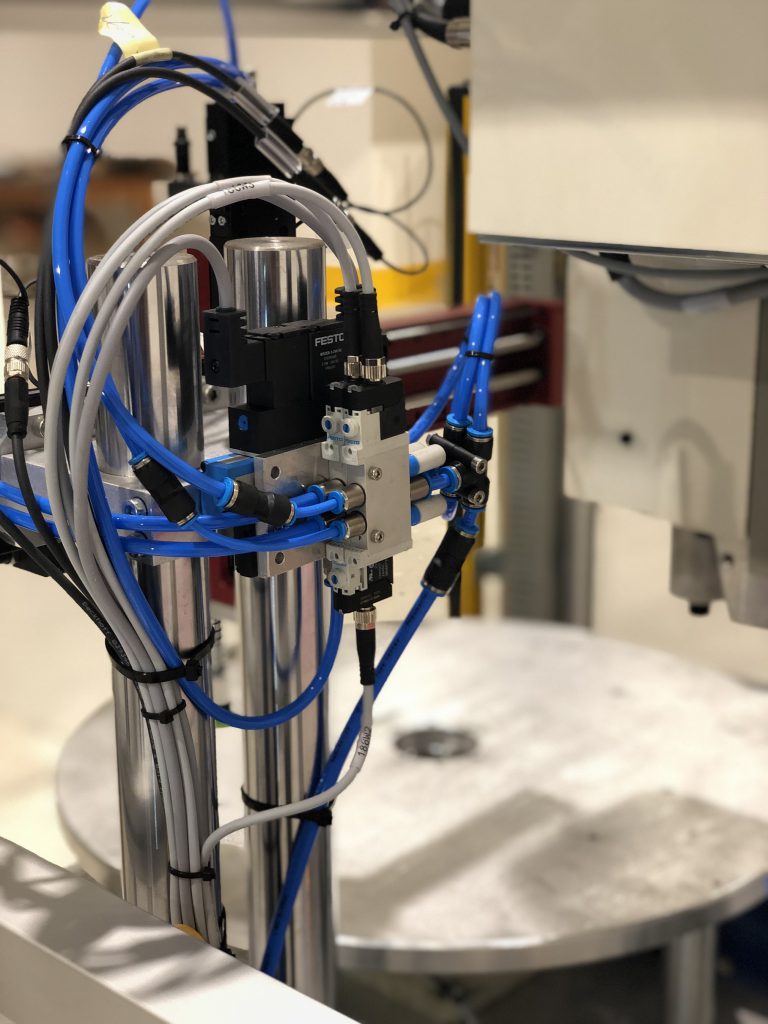

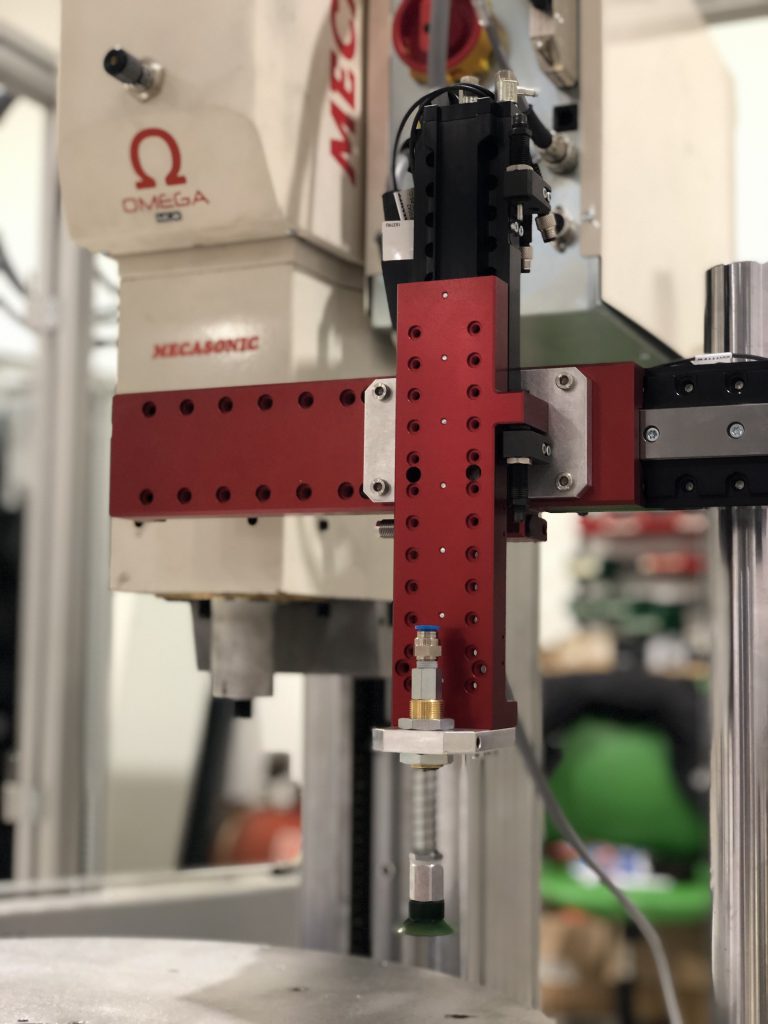

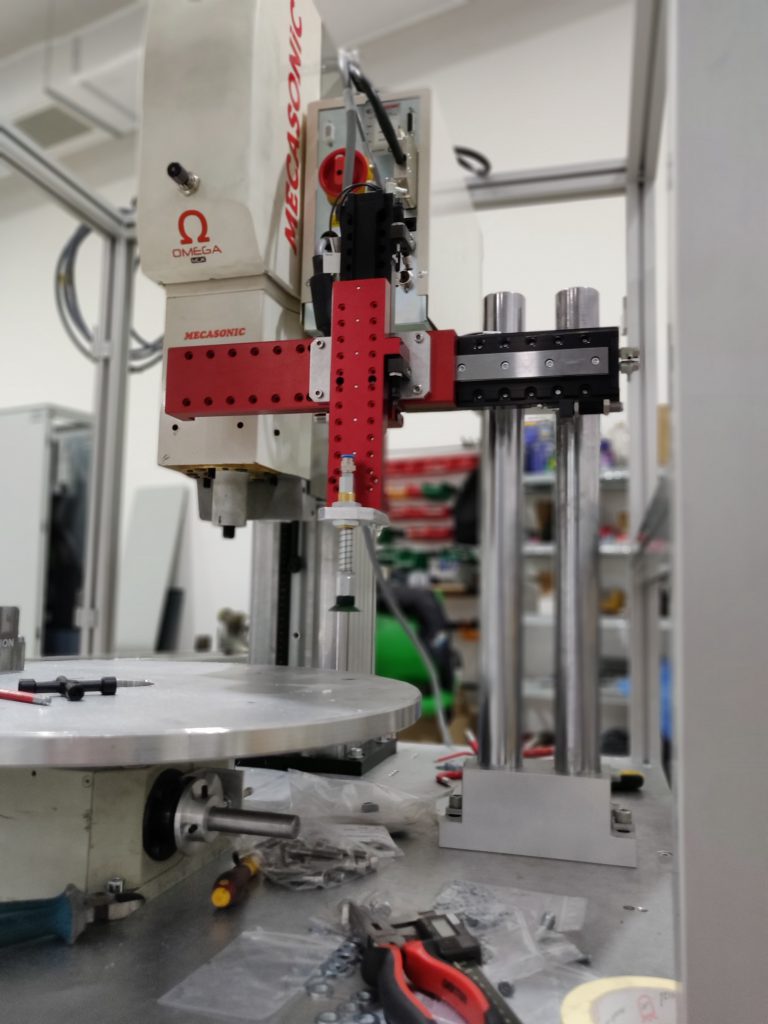

[ezcol_1half_end]For a local customer we have designed and built an ultrasonic welding machine.

This kind of machines can be used for various functions such as component welding, gluing, snapping and so forth.

Ultrasonic welding is an especially gentle joining technology for thermoplastic materials. Manual work stations are used in many ways in the plastics processing industry. The user manually loads the plastic components to be joined and the machine removes them from the ultrasonic welding machine after the weld process.

Partially automated solutions support the work process for the production of high-quality thermoplastic products.[/ezcol_1half_end]

From system integration and smooth start-up to production assistance and professional operator training JMartans provides the general prerequisites for safe process-related implementation of a flexible automation system.

Contact us today for a free consultation.